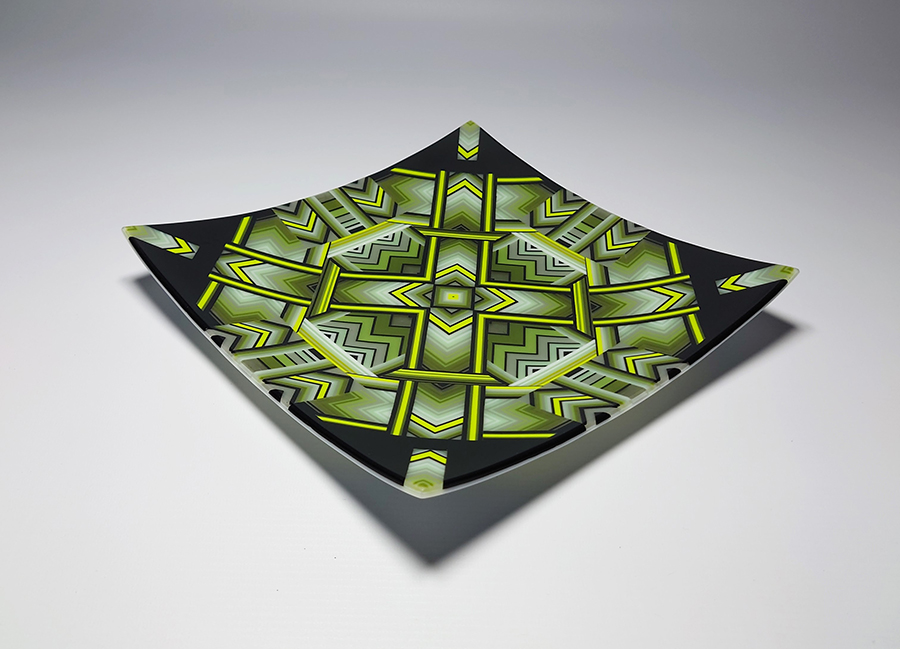

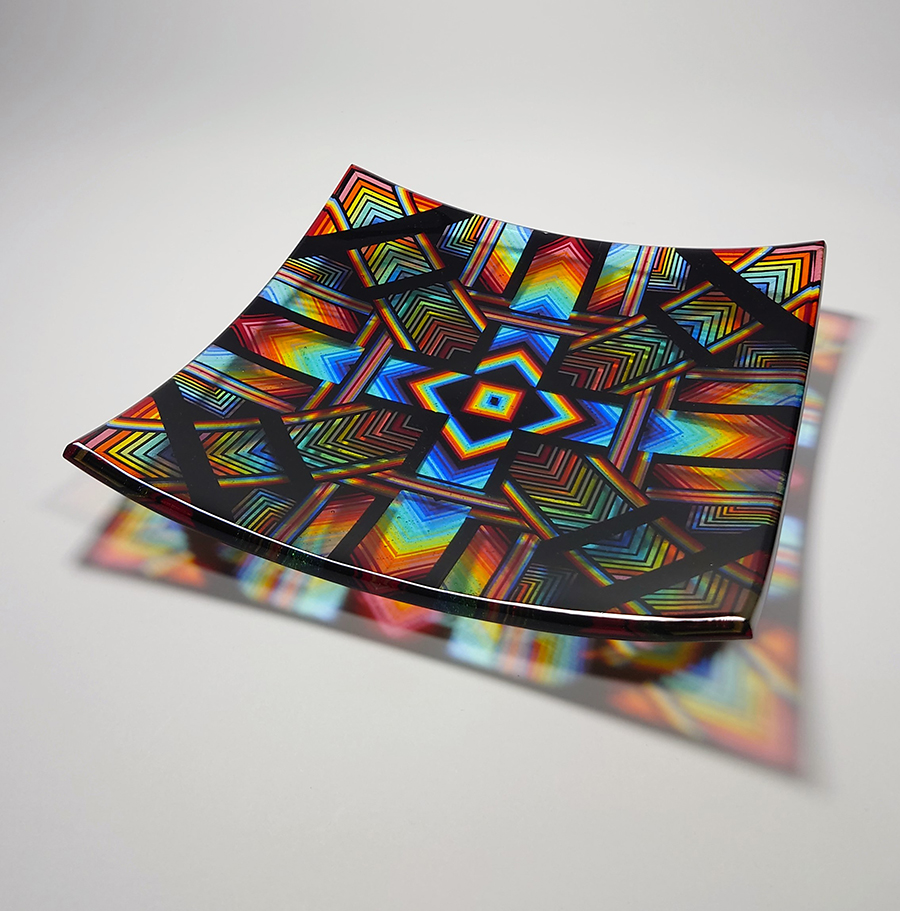

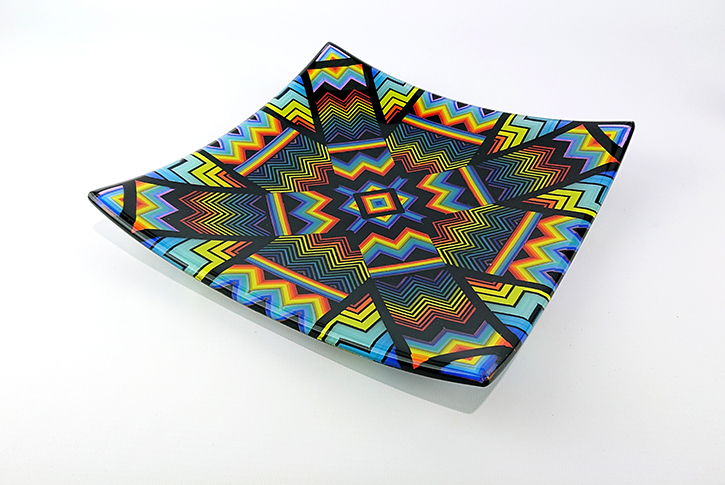

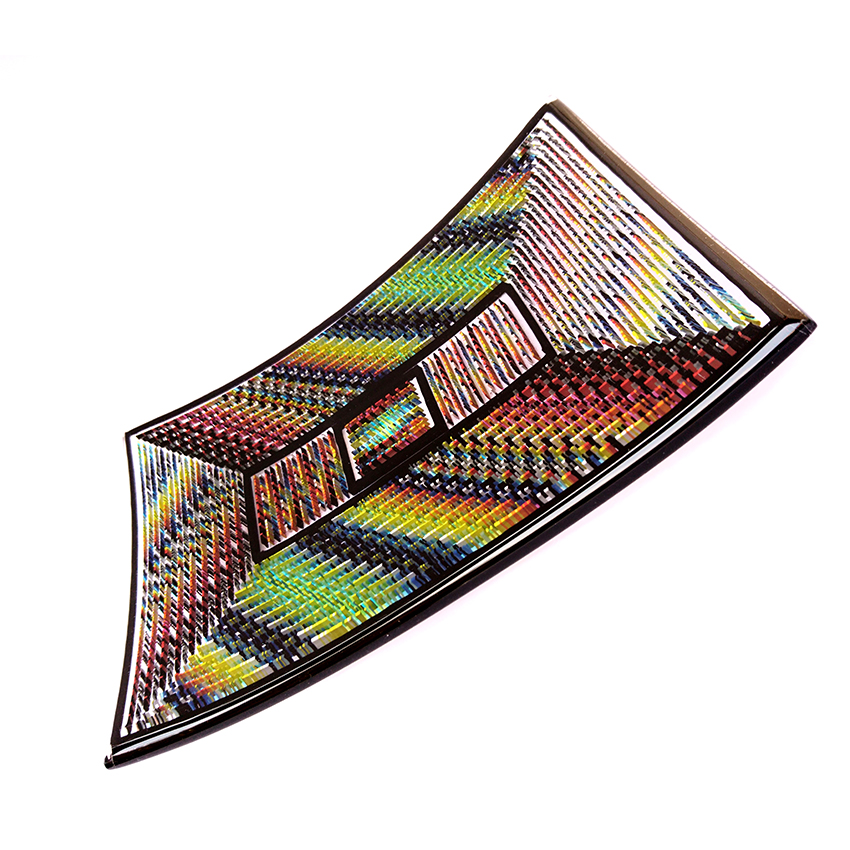

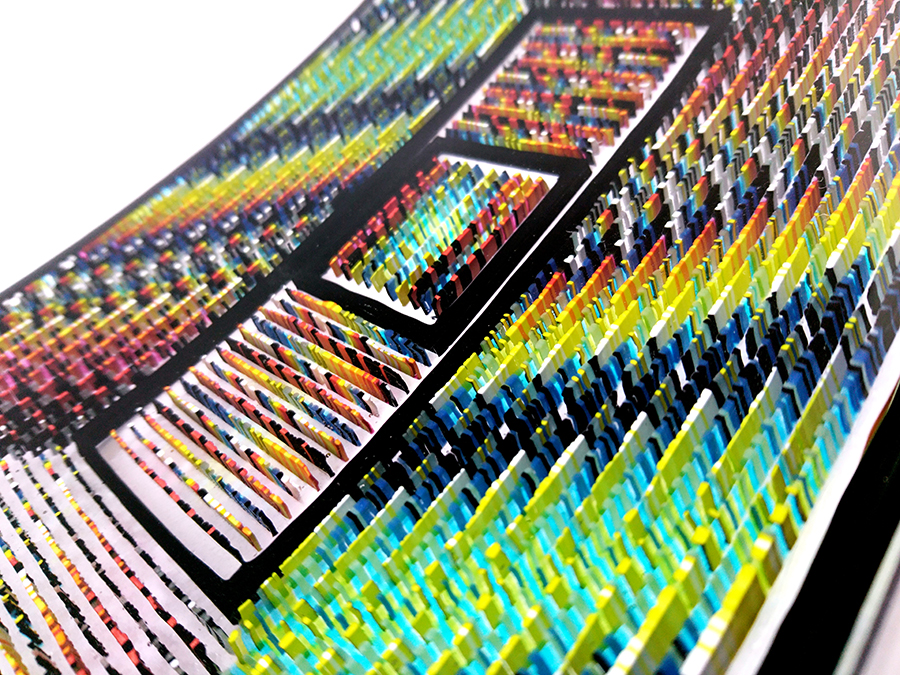

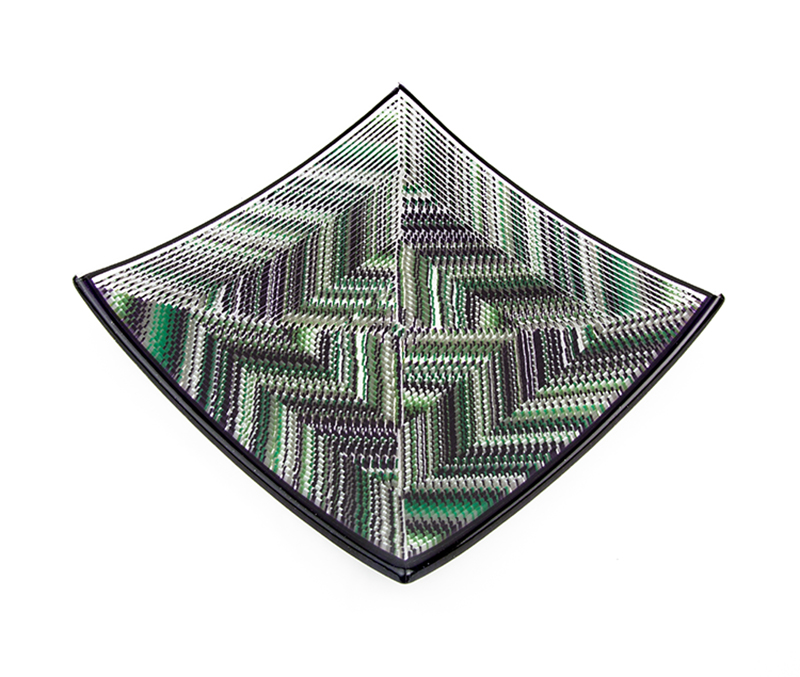

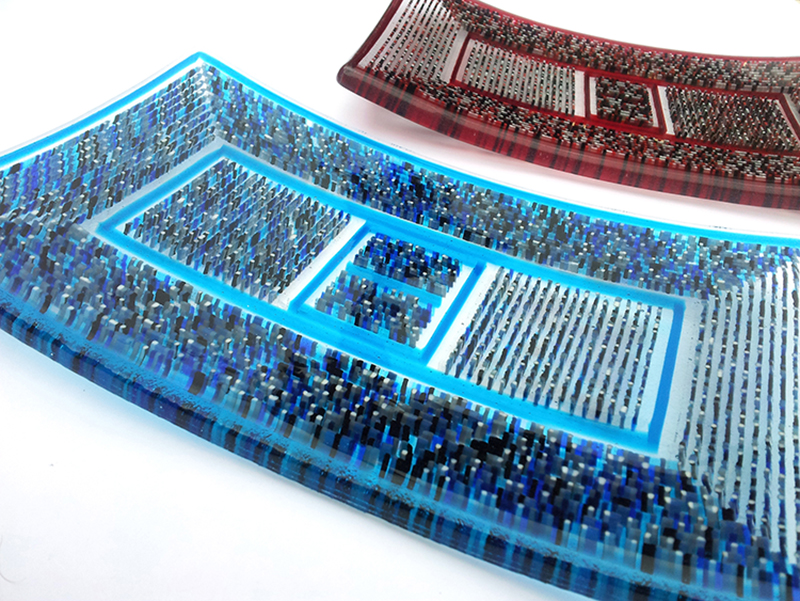

Ian produces a wide variety of kiln-formed glass platters. The form of these glass platters allow for a perfect showcasing of the patterns within Ian’s glass art works. Art no longer needs to be fixed to a wall it can be equally admired as a centre piece on a table…

The process of forming the glass platters requires many stages. Initially the patterns within the glass are formed by kiln-forming a sheet of striped, coloured glass which is then deconstructed and cut into smaller elements which are accurately arranged to form the pattern. This sheet of patterned glass is then melted into a solid sheet of glass within the kiln. Once this sheet of glass is carefully cooled(annealed) then it is removed from the kiln whereupon it is cold-worked using diamond abrasives to achieve the desired shape and surface finish. The piece is then returned to the kiln for a controlled, lower temperature firing which returns a shine to the surface of the glass without losing its form. Once this has cooled(annealed) and is removed from the kiln and then requires shaping. To achieve the shaping of the sheet of patterned glass it is again placed within the kiln whereupon the heat from the kiln softens the glass enough to allow the weight of the glass and gravity to form the glass into its desired shape. The shape is determined using a ceramic former which can be custom made for each size and shape of bowl to be formed. Once the piece of glass has draped with heat and gravity into its desired shape it is again annealed before cooling and removing from the kiln. Each firing within the kiln takes an average of 16 hours and each glass bowl involves a minimum of four separate firings.

Handmade glass platters can be made in various sizes to cater to the space availability/ taste of each individual. To see the latest selection, visit us at one of our shows. Find our more HERE.