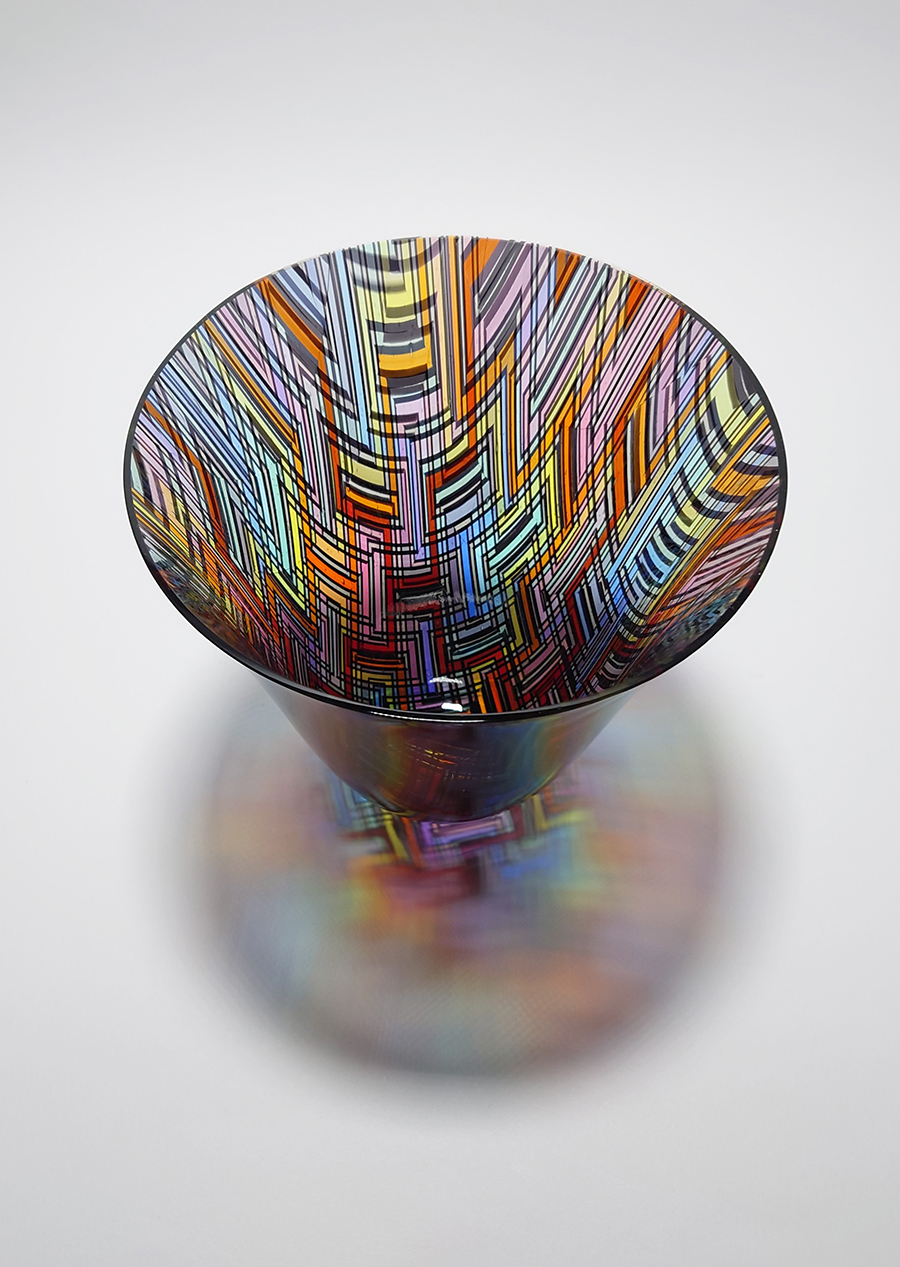

Ian also produces kiln-formed glass vases in many different sizes, colours and forms.

The process of forming the glass vases requires several stages. Initially the patterns within the glass are formed by kiln-forming a sheet of striped, coloured glass which is then deconstructed and cut into smaller elements which are accurately arranged to form the pattern. This sheet of patterned glass is then melted into a solid sheet of glass within the kiln. This sheet of glass is then carefully cooled(annealed) before its removal from the kiln To achieve the shaping of glass into a vase it is again placed within the kiln upon a flat ceramic ring whereupon the heat from the kiln softens the glass enough to allow the weight of the glass and gravity to stretch the glass down through the hole in the ceramic ring until it has stretched to the desired height. Once the vase has reached its desired height the kiln is crash cooled by opening the kiln door to allow a rapid release of heat which cools the glass and halts the vase from stretching further. Once the glass has draped with heat and gravity into its desired shape it is again annealed before cooling and removing from the kiln. The piece is then cut down and cold-worked using diamond abrasives before being polished to a fine finish. Each firing within the kiln takes an average of 16 hours and each glass vase involves a minimum of three separate firings and many hours of work.

Some of the vases pictured within the gallery were produced during my residency at The Glass Hub glass school in Wiltshire. The pieces from this residency are produced by taking kiln-formed glass panels into a glass blowing hot shop where the panels are rolled into a cylinder before being carefully heated and shaped. The finished forms are then carefully annealed before being cold worked with diamond polishing abrasives.